ALTA free library for a great selection of papers

April 9, 2015

5 common misconceptions about process mineralogy

July 28, 2015

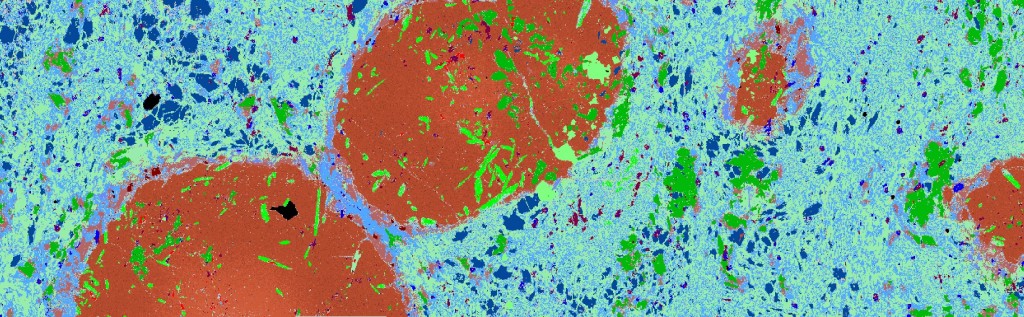

Mineral map of Blueschist taken from Täschalp (Switzerland), sample courtesy of Dr. Sarah Owen

ZEISS have announced the release of version 1.2 of Mineralogic Mining – their automated mineralogy software system. The latest version delivers a host of new features and benefits, including:

– Multiple-system integration

– Expanded suite of measurement modes

– Optimised time to result

– Improved data explorer layout

Multiple-System Integration – Mineralogic is designed to allow you to change and optimise SEM and EDS settings for each analysis whilst still using the same mineral database. Not only does this allow you to get the best data possible, but it also makes it possible to directly share mineral databases between Mineralogic instruments without having to make modifications. For the first time this allows organisations with multiple instruments to integrate workflows and datasets seamlessly.

Expanded Suite of Measurement Modes – Building further on workflow optimization with this latest release, the Mineralogic Mining toolset now offers a range of measurement modes. Within each of these analysis modes are a wide range of user-configurable settings to make the most of the system flexibility. This allows the user to optimize the system for the samples being analysed, and the information required.

Mapping – scans the sample, identifies the areas to be analysed, and undertakes full EDS analysis on every point

Line – scans the sample, identifies the areas to be analysed, and undertakes a single line of EDS analysis through the centre of each particle

Spot – scans the sample, identifies the areas to be analysed, and collects a single EDS analysis from the centre of each mineral

Feature – scans the sample, identifies the areas to be analysed, and rasters the beam over the surface of each mineral to collect an average EDS spectra

Bright phase searching – scans the sample, identifies particles containing minerals with a specific BSE brightness (such as gold or platinum) and undertakes EDS analysis on these target particles

Optimised time to result – Mineralogic is designed to optimise the overall time to result, making it quicker and easier to get to the information you need. As Mineralogic Mining uses fully quantified EDS spectra to undertake mineral identification during the analysis, the data is ready for reporting as soon as a measurement finishes. There is no need to spend additional time manually manipulating data.

Improved Data Explorer – Mineralogic Mining 1.2 also contains a new layout for Mineralogic Explorer aimed at making it quicker and easier to investigate and report results. These include a new data organisation structure, new filtering capability, quicker access to images and a particle data table.

New Sigma Platforms for Mineralogic Mining

ZEISS have recently launched a new range of Sigma field emission SEMs – one of the recommended platforms for Mineralogic Mining – featuring 15 x faster BSD, further reducing time to result for automated mineralogy applications. Watch this short video about the new systems. To find out about the optimum configuration of ZEISS SEM, ranging from conventional SEM to FE-SEM and FIB-SEM, and Mineralogic Mining to improve the productivity of your operations, feel free to contact Zeiss directly.

Would you like to see ZEISS Mineralogic Mining in action? The ZEISS Mining team would be delighted to meet you at the following events and arrange a demo:

Precious Metals, 11-12 May, Falmouth, UK

Geomin, 8-10 July, Antofagasta, Chile

ICAM, 10-12 August, Istanbul, Turkey

SGA Geomet, 24-27 August, Nancy, France

SEG, 27-30 September, Hobart, Tasmania

Procemin, 21-23 October, Santiago, Chile

Flotation, 16-19 November, Capetown, South Africa